When it comes to vehicle safety, the braking system is a true unsung hero, and at the heart of this system are the brake rotors. Often overshadowed by other car parts, brake rotors play a pivotal role in bringing your vehicle to a halt.

Brake Rotors Explained

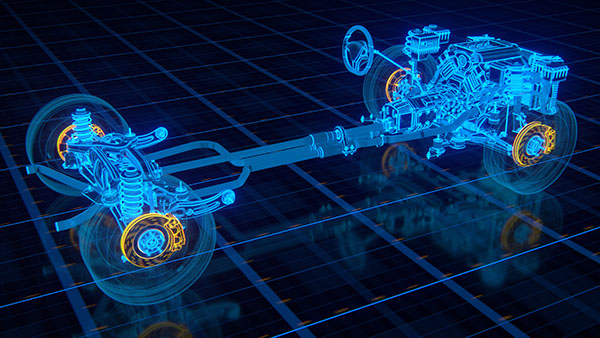

Brake rotors, also known as discs, are robust, flat, and round plates made of high-strength steel. Each rotor is securely mounted to your car's wheel hub, playing a pivotal role every time you need to slow down or stop.

When you press the brake pedal, a fascinating process begins: the brake calipers squeeze the brake pads against the rotors. This action creates friction between the pads and the rotors, converting the kinetic energy of your moving vehicle into thermal energy – heat, in simpler terms. This heat and friction cause the wheels to rotate slower, which in turn slows down your car.

The effectiveness of your brake rotors largely depends on their ability to absorb and dissipate this heat. If they get too hot, their performance can falter, making it crucial to maintain them well. Their durability, resistance to wear, and capacity to handle high temperatures are what keep you safe on the road.

The Connection Between Brake Rotors and Pads

The interplay between brake rotors and pads is a masterclass in automotive engineering. These two components work in tandem to ensure your vehicle stops when you need it to.

The brake pads are designed with a friction material on one side, which makes contact with the rotors. When you apply the brakes, hydraulic pressure from the brake fluid pushes these pads against the rotors.

The surface of the rotor needs to be smooth and flat for the pads to work effectively. Any irregularity on the rotor can reduce the brake pad's contact area, diminishing braking efficiency. Some pads are softer, causing less wear on the rotors, while others are harder and more durable but can be tougher on the rotor surface.

Best and Worst Maintenance Practices

Here are some best practices and common pitfalls in brake rotor maintenance:

Do's:

- Over time, they wear down, becoming thinner and less effective at dissipating heat. If they get too thin, they can overheat and even warp, which significantly hampers their performance. Measuring their thickness during routine maintenance helps quite a lot - you will know when it's time for a replacement.

- The choice of brake pads is vital. Different materials can affect rotor wear differently. For instance, ceramic pads are gentler on rotors than metallic pads but might not perform as well in harsh conditions.

Don'ts:

- Ignoring noises like grinding or squeaking from your brakes is a gamble with your safety. These sounds often indicate that your brake pads are worn down, allowing metal-to-metal contact, which can quickly damage your rotors.

- Skipping regular brake inspections is like flying blind. Brake rotors don't wear down overnight; it's a gradual process. Periodic check-ups by professionals can catch wear and tear early, preventing costly repairs and ensuring your brakes are always ready for action.

Signs Of Bad or Worn-Out Brake Rotors

Here are some red flags indicating that your brake rotors need attention:

- If you feel a wobbling or pulsating sensation in the pedal or steering wheel when you brake, it could mean your rotors are warped.

- Over time, rotors can develop deep grooves or score from regular use, indicating it's time for them to be replaced.

- Rotors wear down over time. If they become too thin, they won't dissipate heat effectively, compromising braking performance.

- Unusual sounds like grinding, squealing, or scraping when braking can point to rotor problems.

For expert brake system repairs and maintenance, contact EAS Tire & Auto, and our team will be more than glad to help! Your safety on the road is our priority.